Welcome to the official website mall of Shanghai Rainminda Pharmaceutical Technology Co., Ltd

EN

Welcome to the official website mall of Shanghai Rainminda Pharmaceutical Technology Co., Ltd

CHO Cell Expression System

1、Business (Product) Name:CHO cell expression system

2、Overview of Service (Product) Content:

The mammalian cell expression system can provide post-translational modifications to recombinant human proteins bringing them closer to their natural state. During protein expression, it facilitates protein folding and polymerization similar to those of natural proteins, ensuring the necessary spatial structure and modifications for active proteins. The exogenous proteins produced by mammalian cells through translation and processing modification have higher activity than prokaryotic expression systems and eukaryotic expression systems such as yeast and insect cells, and are closer to natural proteins. This capability makes mammalian cell expression systems particularly useful in the development and production of recombinant protein drugs, especially therapeutic recombinant monoclonal antibodies. Binhui Biopharma has established a mature mammalian protein expression system and purification service platform, providing expression and purification services for mammalian protein expression systems.

Rainminda Pharmaceutical's mammalian cell protein expression technology team, with extensive experience in CHO and HEK293 cell expression, meets various specialized requirements, including label excision, endotoxin removal, and serum-free suspension culture to provide services to customers.

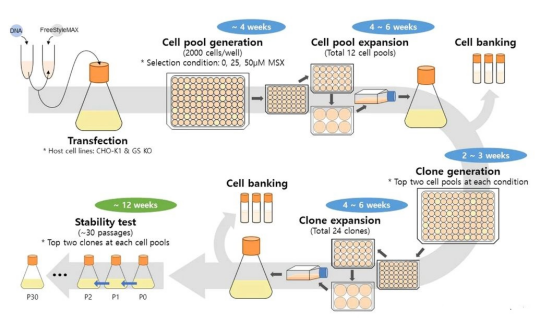

3、 Service (process) route :

4、 Typical data or result display:

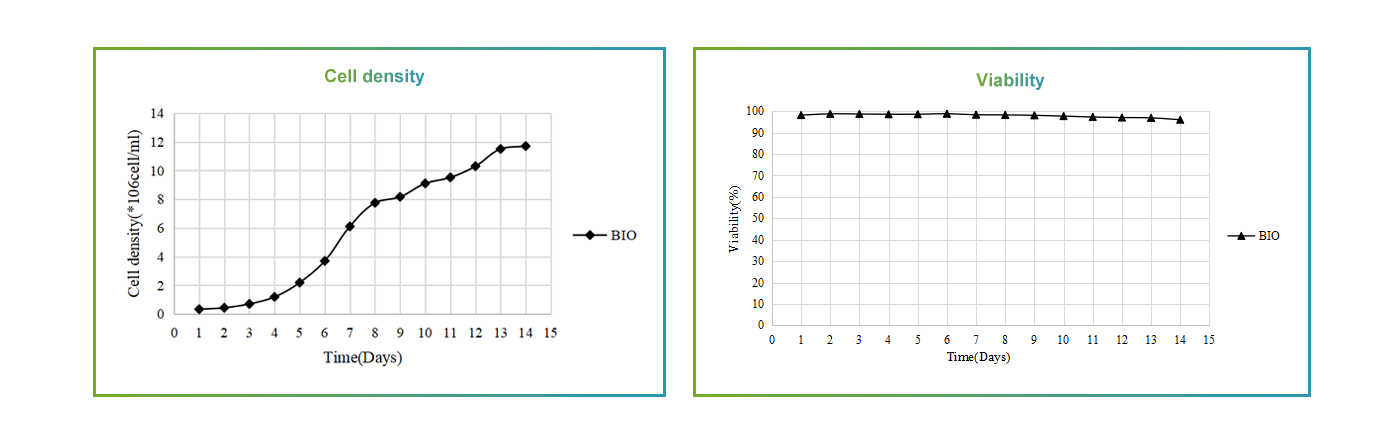

The CHO-K1 stably transformed cell line was cultured in the bioreactor to express PF-D (recombinant COVID-19 S protein trimer). The cell concentration and viability are shown as follows:

The highest cell concentration can reach 1.17 × 107/ml, and the cell survival rate remains above 95%. Culture until the 14th day and remove from the tank.

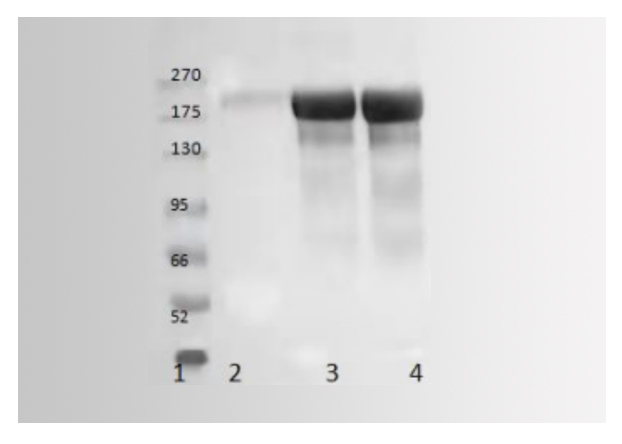

According to WB preliminary assessment, the protein expression level can reach 500mg per liter when cultured in the bioreactor until the 13th day.

5、 Core advantages or characteristics

CHO-K1 cells in eukaryotic cells are currently the preferred system for producing recombinant glycoproteins, as they have many advantages compared to other expression systems:

①Having accurate post-transcriptional modification function, the expressed glycosylated drug protein is closest to natural protein molecules in terms of molecular structure, physicochemical properties, and biological functions;

②Having the function of extracellular separation of products, facilitating downstream product separation and purification;

③Efficient amplification and expression ability of recombinant genes;

④It has the characteristics of adherent growth, high tolerance to shear force and osmotic pressure, and can be cultured in suspension with high expression levels;

⑤CHO cells belong to fibroblasts and rarely secrete their own endogenous proteins, which facilitates the separation and purification of downstream products;

⑥It can achieve high-density cultivation in suspension culture or serum-free medium, with a cultivation volume of 50-100L or more, and can be produced on a large scale.

6、 Project (Product) Experience

Instantaneous transfection: A certain amount of soluble protein can be obtained in a short period of time, which can be used for rapid expression of gene products and small-scale preparation of proteins.

Process: Design and synthesis of target gene sequence → Construction of target gene into expression vector → Transient expression → Recombinant protein purification → QC detection and shipment

Expression types: conventional monoclonal antibodies, proteins, etc Delivery quantity: 100μg~10mg

Host cells: HEK293/CHO QC testing:SDS-PAGE>95%

Stable transfection: Stable and high-yield, can be used for industrial production

Process: Design and synthesis of target gene sequence → Construction of target gene into expression vector → Electrophoresis → Screening of monoclonal stable transfection cell lines → Expression evaluation and detection → Amplification and recombinant protein purification → QC& delivery

Mr. Xu 19025438700

Business Cooperation:

Dr. Xu 19025438700 WeChat:xiaoboo365

Virus Vector:

Manager Shi 15391503730 WeChat:shixiaotai611

Nucleic Acid Products:

Manager Ni 13437112357 WeChat:go-ahead-no-back

Protein Products:

Manager Zhou 18771147489 WeChat:huhu_ai_junjun

Genetic Products:

Manager Wang 13067989761 WeChat:wry12121

Instrument and Equipment:

Manager Ni 13437112357 WeChat:go-ahead-no-back

Test Kit:

Manager Liu 15207178732 WeChat:Q15207178732

xuxiaobo@binhui-bio.com